Photovoltaic System

Series Inverters: These are used to convert the DC power generated by solar panels into AC power, which can be used by homes or businesses.

Micro Inverters: These inverters are installed at the panel level, converting DC to AC for each solar module, allowing for better performance and energy yield in systems with shading or varied panel orientation.

Energy Storage Modules: These are designed to store excess energy generated by the solar system for use during periods of low sunlight or power outages.

Fast Shutters: Likely referring to automated or rapid-response devices that protect the system by disconnecting or shutting down certain parts of the system in the event of issues like overvoltage or faults.

Smart Junction Boxes: These are the central connection points for multiple solar panels, ensuring safety, monitoring, and sometimes optimization of the energy output across the system.

Each of these components is crucial for optimizing and safeguarding the performance of photovoltaic systems, with MD TECH providing adhesive solutions to ensure durability and efficiency in these critical elements.

Series Inverters

Series inverter is mainly used by glue point is its inductor heat conduction potting, wire harness reinforcement fixing, shell sealing, bonding fixed inductor coil and other structures, heat dissipation of heating components and circuit board protection.

| Model | Application point | Product type | Component | Curing condition | Advantage |

| MDTIM 6230(15#) | Inductance conduction potting | Silicone | 2K | Room temperature/heat cure | Heat conduction 1.5W/m.K |

| MDSI 7333 | Harness reinforcement fixed | Silicone | 1K | Room temperature | The dry time is 3 minutes |

| MDSI 7336 | Shell bonding | Silicone | 1K | Room temperature | Flame retardant type |

| MDSI 7317 | Shell bonding | Silicone | 1K | Room temperature | Heat conduction 1.6W/m.K |

| MDEP 3211 | Bond the fixed inductor | Epoxy | 2K | Room temperature/heat cure | Strong adhesion to various substrates |

| MDCOAT 7062 | Circuit board three protection | Silicone | 1K | Room temperature | Low viscosity, environmentally friendly |

| MDTIM Gap filler | Heat dissipation of heating components | Silicone | 2K | Room temperature/heat cure | Thermal conductivity 2.0-3.5W /m.K |

Micro inverters: Development history of domestic micro inverters

2008: China's first micro reverse was born, using BESIL 8230 self-adhesive thermal and flame retardant potting silicone

2018: China's one million micro reverse shipments, using BESIL 8230 self-adhesive thermal and flame retardant potting silicone

2020: China's two million micro reverse shipments, using BESIL 8230 self-adhesive thermal and flame retardant potting silicone.

| Model | Application point | Product type | Component | Curing condition | Advantage |

| MDTIM 6230(1#) | Heat conduction potting | Silicone | 2K | Room temperature/heat cure | Self-adhesive heat conduction can be repaired |

| MDSI 7096 | Sealing material | Silicone | 1K | Room temperature | The dry time is 3 minutes |

| MDSI 7091 | Solder joint protection | Silicone | 1K | Room temperature | Flame retardant type |

| MDTIM Gap filler | Heat dissipation of heating components | Silicone | 2K | Room temperature/heat cure | Thermal conductivity 2.0-3.5W /m.K |

Contact Us

Ask for Sample&TDS

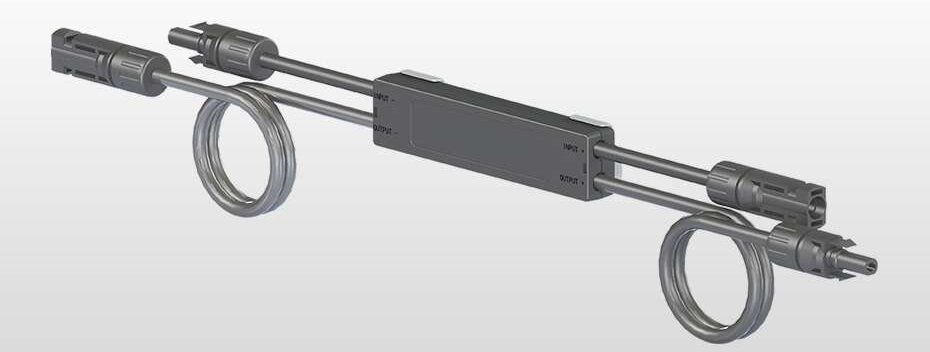

The glue points used for quick shut-off mainly include PCB thermal waterproof potting, wire harness waterproof fixing, solder joint protection, etc.

| Model | Application point | Product type | Component | Curing condition | Advantage |

| MDTIM 6230(1#) | Heat conduction potting | Silicone | 2K | Room temperature/heat cure | Self-adhesive heat conduction can be repaired |

| MDSI 7096 | Waterproof fixing of wiring harness | Silicone | 1K | Room temperature | The dry time is 3 minutes |

| MDSI 7091 | Solder joint protection | Silicone | 1K | Room temperature | Flame retardant type |

Contact Us

Ask for Sample&TDS

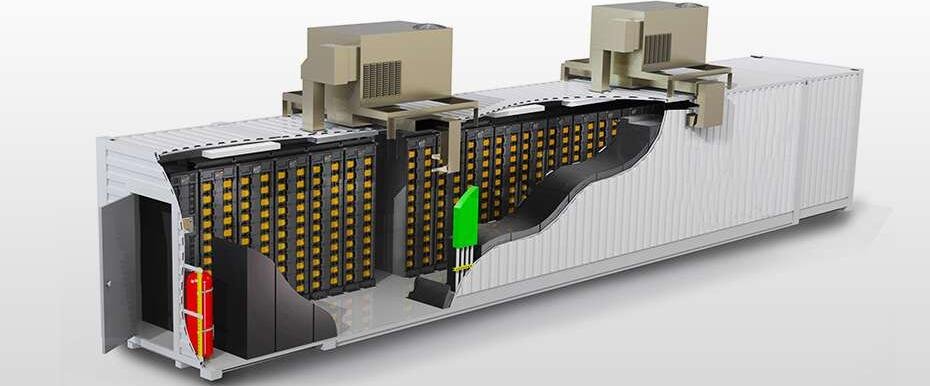

For the energy storage system of new energy generation, there are many adhesive application scenarios.

Including battery pack filling and fixing, to BMS three defense, and then to the shell bonding and sealing, hydrogen energy reactor heat conduction filling and sealing.

All kinds of wiring harness bonding and fixing, in addition, the bottom of the electric cabinet can also do moisture-proof and waterproof potting treatment.

| Model | Application point | Product type | Component | Curing condition | Advantage |

| MDPU 8110 | Cell bonding | PU | 2K | Room temperature/heat cure | Rapid curing |

| MDPU 8650 | Cell bonding | PU | 2K | Room temperature/heat cure | Thermal conductivity 1.2W/m.K |

| MDCOAT 7062 | BMS circuit board three anti-covering | Silicone | 1K | Room temperature | Flame retardant type |

| MDSI 7096 | Pack housing is bonded and sealed | Silicone | 1K | Room temperature | Seal and bond |

| MDSI 6520 | Pack housing is bonded and sealed | Silicone | 2K | Room temperature/heat cure | Seal and bond |

| MDTIM Gap filler | Fixing of heat conduction at the bottom of the cell | Silicone | 2K | Room temperature/heat cure | Thermal conductivity 2.0-3.5W /m.K |

Contact Us

Ask for Sample&TDS

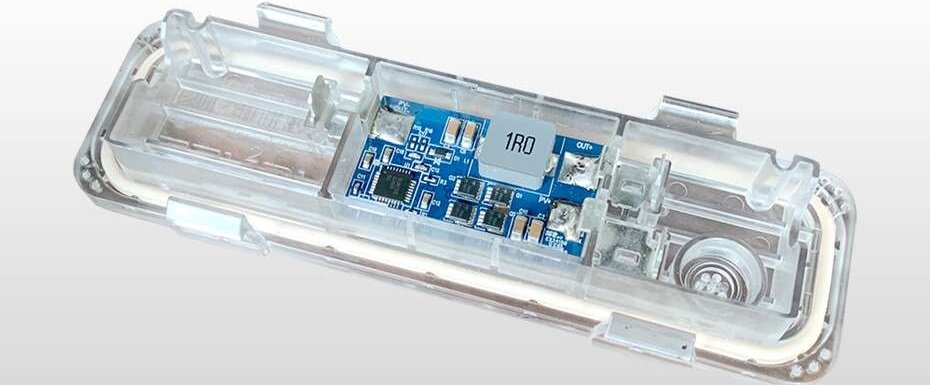

Smart junction box with adhesive points mainly PCB thermal waterproof potting, junction box and photovoltaic panel bonding, solder joint protection.

| Model | Application point | Product type | Component | Curing condition | Advantage |

| MDTIM 6230(1#) | Heat conduction potting | Silicone | 2K | Room temperature/heat cure | Self-adhesive heat conduction can be repaired |

| MDSI 7096 | Bonding between junction box and photovoltaic panel | Silicone | 1K | Room temperature | The dry time is 3 minutes |

| MDSI 7091 | Solder joint protection | Silicone | 1K | Room temperature | Flame retardant type |

Contact Us

Ask for Sample&TDS