Silicone Conformal Coating vs. UV Conformal Coating: Key Differences and Selection Guide

As critical protective materials in electronics manufacturing, automotive industries, and renewable energy sectors, the choice of conformal coating directly impacts product performance and longevity. This article provides an in-depth analysis of the technical distinctions between silicone Conformal Coating and UV acrylic Conformal Coatingto help you make informed decisions.

I. Key Differences Comparison

1. Material Properties

- Silicone Conformal Coating

- Composition : Silicone resins and modified silicone compounds.

- Features : Exceptional temperature resistance (-60°C to 250°C), high flexibility, superior weather resistance, chemical inertness.

- Curing : Thermal or moisture curing; longer curing time (minutes to hours).

- UV Conformal Coating

- Composition : Acrylate-based prepolymers.

- Features : High hardness, strong adhesion, rapid curing (seconds), chemical corrosion resistance.

- Curing : UV light activates photoinitiators; requires specific wavelength (typically 365nm).

2. Performance Comparison

|

PROPERTY

|

SILICONE COATING

|

UV ACRYLIC COATING

|

|---|---|---|

|

Temperature Resistance

|

Excellent (wide range stability)

|

Moderate (-40°C to 120°C)

|

|

Flexibility

|

High (impact-resistant)

|

Low (rigid and brittle)

|

|

Curing Speed

|

Slow

|

Extremely fast (ideal for automation)

|

|

Weather Resistance

|

UV-resistant, anti-aging

|

Prone to yellowing under UV exposure

|

|

Dielectric Performance

|

Superior (high-frequency applications)

|

Good (general electronics protection)

|

3. Application Scenarios

- Silicone Coating :

✅ LED encapsulation, automotive electronics, solar panel sealing, high-temperature sensors.

✅ Components exposed to outdoor environments or frequent thermal cycling. - UV Acrylic Coating :

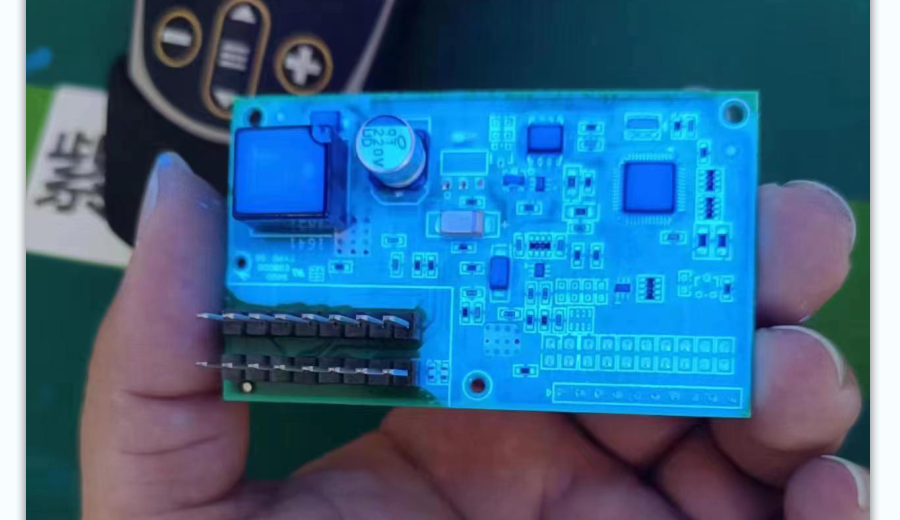

✅ Precision PCB protection, optical lens bonding, medical device encapsulation.

✅ High-speed production lines requiring rapid curing and precise coating.

II. Selection Decision Guide

1. Based on Operating Environment

- High-Temperature/Extreme Conditions : Silicone (e.g., engine compartment electronics).

- Chemical-Exposed Environments : UV acrylic (better resistance to acids, solvents).

2. Based on Production Requirements

- Mass Production Efficiency : UV acrylic (seconds-level curing boosts throughput).

- Complex Geometries : Silicone (penetrates gaps without light-dependent curing).

3. Cost-Benefit Analysis

- Initial Cost : Silicone has lower material costs but higher curing energy consumption.

- Total Cost : UV acrylic reduces labor and energy costs for high-volume applications.

III. MDTEH Recommendations

As a conformal coating supplier with 19 years of R&D expertise, we recommend:

- Free Sample Testing : Validate performance under real-world conditions with our samples.

- Custom Solutions : Tailored formulations for specialized needs (flame retardancy, thermal conductivity, etc.).

- Technical Support : End-to-end assistance from coating processes to equipment selection.